We’re lucky to be a part of a significant digitization of manufacturing, a transformation so compelling, that it is being called Industry 4.0 to represent the fourth revolution that has occurred in manufacturing. in this article will discuss on AR & VR in the Era of Industry 4.0.

As it is said that our world and its occupants are living in the age of information outburst, which also means that huge amounts of data is being created every day and this amount of data being created has increased drastically in the last 3 years. But the quantity of data isn’t important but what is more important is how it improves the process of taking decisions.

It is the point where intelligent connections are important. People and machines are connected throughout in industry 4.0 , improving the industrial processes. But the industrial revolution 4.0 does not rely only on technologies like AI, ML, Iot, Blockchain etc it’s not just a single technology, but also uses experiential technologies like Augmented Reality or AR and VR or Virtual Reality.

Augmented Reality and its effect in the Industry 4.0

Augmented Reality or AR takes into account the group of technologies that allows looking at the environment of real world in an enhanced augmented way by graphics which are computer generated. AR or Augmented reality has different applications, but manufacturing can be cited as an area that can benefit the most from augmented reality.

It can range from designing to prototyping, the production and assembly, thorough maintenance, all of these have their challenges but it is AR that can prove to be a boon for accomplishment of these complex processes. This is because of AR’s capability to simulate, help and enhance the work of these processes even before they are started.

Uses of AR or Augmented Reality in the era of Industry 4.0

Helpful in Complex Assembly:

Augmented Reality can assist in complex assemblies of the modern manufacturing industry. Generally the work documents are created in PDF format. This can be difficult to understand but Augmented Reality helps to make work documents in pdf format into a video. They are made hands-free along with being voice-controlled. AR helps to break down the instructions and the video can further be added. This process can be seen through AR glasses.

Maintenance:

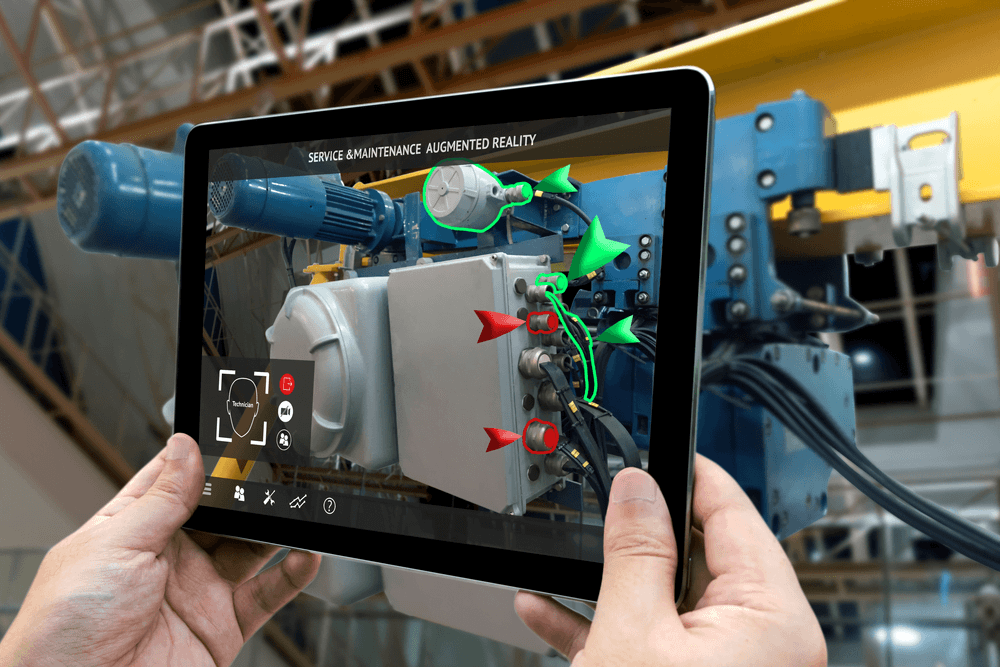

After helping in the complex assembly, AR plays an important role in the maintenance area as well. These days workers perform the task of maintenance manually by making use of a manual. But the process is tiring, takes a lot of time and is also prone to errors. But after involving AR into the process, the status of the machine can be checked easily by just looking at it through the AR glasses that can be a great and staunch maintenance tool.

Provides Expert Support:

When there is some kind of disturbance in the manufacturing process, there is need for an expert to visit the factory or site of work and solve it. Although there are many technicians present at the site, but experts are less. Augmented Reality helps to cut down the expense of employing more and more experts in fact it can make it possible for an expert to support the technician and inspect the disturbance from any part of the world.

Virtual Reality or VR in the era of Industry 4.0

Virtual Reality will definitely be enacting a top role in the era of Industry 4.0. VR unlocks different avenues to create smart and intelligent solutions as the manufacturing sector and its units partner with intelligent machines, good connectivity, platforms of data intelligence along with simulation tools. All of these positive changes will help to refine the production capability to meet the needs of customers.

Virtual Reality or VR Applications Uses in Industry 4.0

Training:

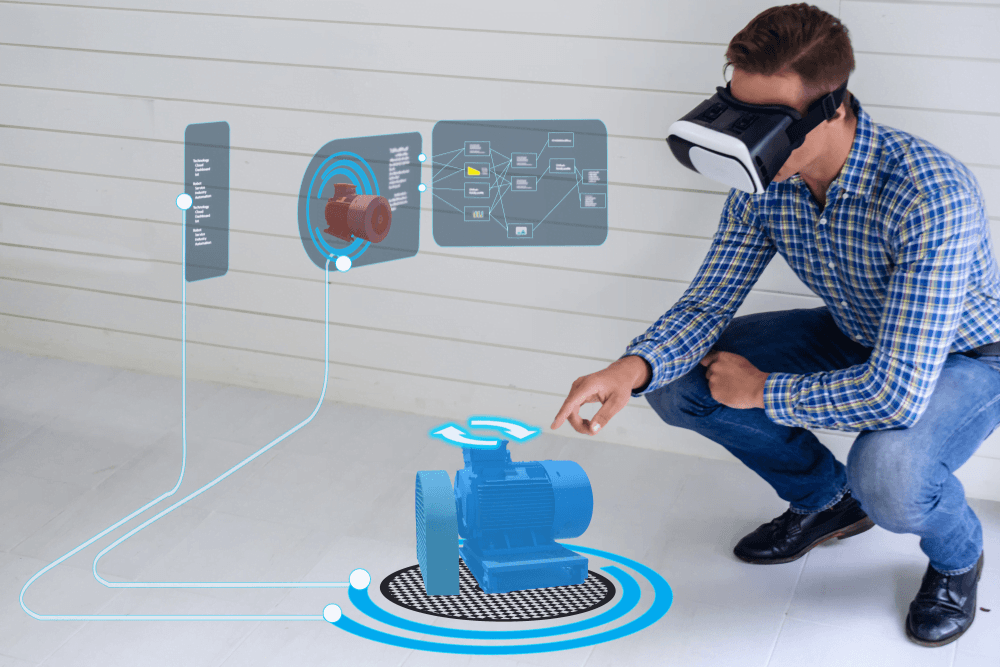

VR greatly helps the companies to provide their employees with the real environment in a virtual manner.Training for eliminating the distractions like noise, humans, etc help the workers to focus on their work and increase their productivity.

Planning :

To build a plant or to renovate the existing one would require lots of efforts. But in these cases virtual plants come to the rescue as they can be tested as many times as desired in order to find the flaws of the whole system and also to correct them.

Safety Inspections :

The routine safety inspections with the help of VR can be easily carried out by the trained experts. It makes use of virtual manufacturing process environment. We all know that when anything is done manually it is prone to errors, that is why to avoid errors of manual checking and inspecting virtual reality, makes it seamless for the experts to take the smallest of the details into consideration.

Conclusion

The use of VR and AR in manufacturing and other industries or the Industry 4.0 is bound to accelerate as the benefits of these two technologies are becoming increasingly clear.

Industry 4.0 takes into account areas like big data, Blockchain, Artificial Intelligence, E-Commerce, Robotics, Internet of Things etc. By incorporating Augmented Reality and Virtual Reality with their workflow, these two would definitely result into bigger things.